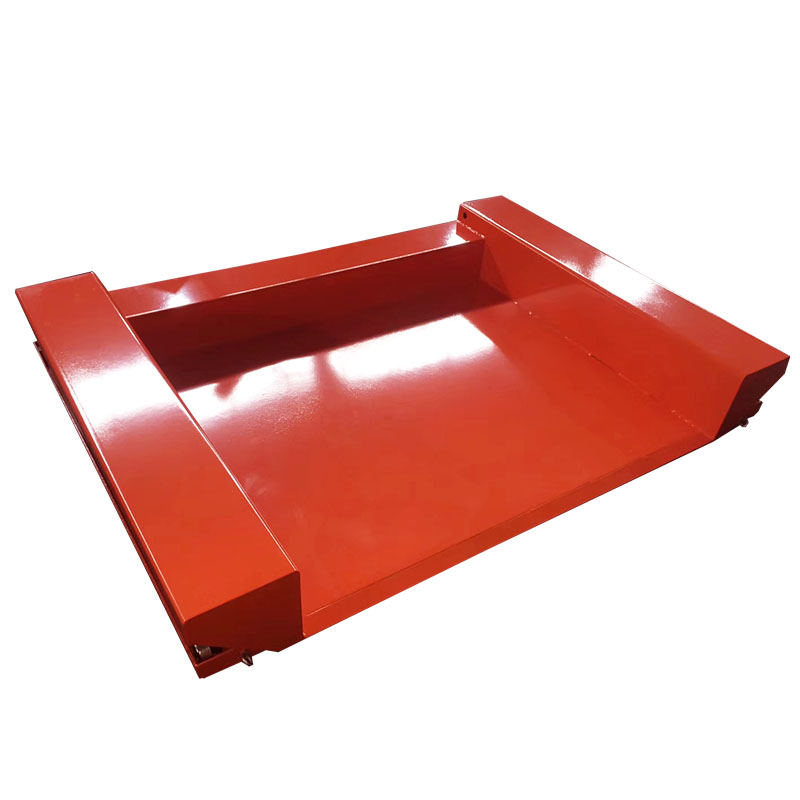

Customized Roller Type Scissor Lift Platforms

Customized roller type scissor lift platforms are highly flexible and powerful devices primarily used to handle a variety of material handling and storage tasks. Below is a detailed description of its main functions and uses:

Main function:

1. Lifting function: One of the core functions of roller scissor lift tables is lifting. Through the ingenious design of the scissor mechanism, the platform can achieve fast and smooth lifting movements to meet the working needs of different heights.

2. Roller conveying: The surface of the platform is equipped with rollers, which can rotate to facilitate the movement of materials on the platform. Whether feeding or discharging, the roller can help the material flow more smoothly.

3. Customized design: According to the specific needs of users, hydraulic roller type scissor lifters can be customized. For example, the size of the platform, lifting height, number and arrangement of rollers, etc. can all be adjusted according to actual needs.

Main purpose:

1. Warehouse management: In warehouses, stationary scissor lift platforms can be used to store and pick up goods. Thanks to its lifting function, it can easily reach different shelf spaces for efficient warehouse management.

2. Production line material handling: On the production line, roller scissor lift tables can be used to move materials between different heights. Through the rotation of the drum, materials can be quickly moved to the next process, improving production efficiency.

3. Logistics center: In the logistics center, customized hydraulic scissor lifts also play an important role. It can help achieve rapid classification, storage and pickup of goods, improving the efficiency of the entire logistics process.

Technical Data

|

Model |

Load capacity |

Platform size (L*W) |

Min platform height |

Platform height |

Weight |

|

1000kg Load Capacity Standard Scissor Lift |

|||||

|

DXR 1001 |

1000kg |

1300×820mm |

205mm |

1000mm |

160kg |

|

DXR 1002 |

1000kg |

1600×1000mm |

205mm |

1000mm |

186kg |

|

DXR 1003 |

1000kg |

1700×850mm |

240mm |

1300mm |

200kg |

|

DXR 1004 |

1000kg |

1700×1000mm |

240mm |

1300mm |

210kg |

|

DXR 1005 |

1000kg |

2000×850mm |

240mm |

1300mm |

212kg |

|

DXR 1006 |

1000kg |

2000×1000mm |

240mm |

1300mm |

223kg |

|

DXR 1007 |

1000kg |

1700×1500mm |

240mm |

1300mm |

365kg |

|

DXR 1008 |

1000kg |

2000×1700mm |

240mm |

1300mm |

430kg |

|

2000kg Load Capacity Standard Scissor Lift |

|||||

|

DXR 2001 |

2000kg |

1300×850mm |

230mm |

1000mm |

235kg |

|

DXR 2002 |

2000kg |

1600×1000mm |

230mm |

1050mm |

268kg |

|

DXR 2003 |

2000kg |

1700×850mm |

250mm |

1300mm |

289kg |

|

DXR 2004 |

2000kg |

1700×1000mm |

250mm |

1300mm |

300kg |

|

DXR 2005 |

2000kg |

2000×850mm |

250mm |

1300mm |

300kg |

|

DXR 2006 |

2000kg |

2000×1000mm |

250mm |

1300mm |

315kg |

|

DXR 2007 |

2000kg |

1700×1500mm |

250mm |

1400mm |

415kg |

|

DXR 2008 |

2000kg |

2000×1800mm |

250mm |

1400mm |

500kg |

|

4000Kg Load Capacity Standard Scissor Lift |

|||||

|

DXR 4001 |

4000kg |

1700×1200mm |

240mm |

1050mm |

375kg |

|

DXR 4002 |

4000kg |

2000×1200mm |

240mm |

1050mm |

405kg |

|

DXR 4003 |

4000kg |

2000×1000mm |

300mm |

1400mm |

470kg |

|

DXR 4004 |

4000kg |

2000×1200mm |

300mm |

1400mm |

490kg |

|

DXR 4005 |

4000kg |

2200×1000mm |

300mm |

1400mm |

480kg |

|

DXR 4006 |

4000kg |

2200×1200mm |

300mm |

1400mm |

505kg |

|

DXR 4007 |

4000kg |

1700×1500mm |

350mm |

1300mm |

570kg |

|

DXR 4008 |

4000kg |

2200×1800mm |

350mm |

1300mm |

655kg |

Application

Oren, an Israeli customer, recently ordered two roller lifting platforms from us for material handling on his packaging production line. Oren's packaging production line is located in an advanced manufacturing plant in Israel and needs to handle a large number of goods every day, so he urgently needs efficient and reliable equipment to improve production efficiency.

Our roller lifting platform fully meets Oren's production needs with its excellent lifting function and stable roller conveying system. The two pieces of equipment are installed at key locations on the packaging line and are responsible for handling and positioning goods between different heights. The rotating function of the drum ensures that the goods can be transported to the next process easily and quickly, greatly improving the efficiency of the production line.

When it comes to safety, our roller lifts also excel. The platform is equipped with multiple safety protection devices, such as emergency stop buttons, overload protection, etc., to ensure the safety of employees during operation.

Since the installation of two roller lifting platforms, the efficiency of Oren's packaging production line has been significantly improved. He was very satisfied with our products and services, and said that these two pieces of equipment not only improved production efficiency, but also reduced workers' labor intensity. In the future, Oren plans to continue to expand production scale and hopes that we can provide him with more advanced equipment and technical support.