Economic Trolley Vacuum Glass Lifter

The indoor glass door is equipped with a suction cup trolley, electric suction and deflation, manual lifting and movement, convenient and labor-saving.This type suction cup trolley cost low but with more efficient working for easy glass handling.if you don’t have enough budget for the project this type glass lifter trolley will be your best choice!

FAQ

A: Its loading capacity range is 300kg-400kg.

A: Our products have been certified by the European Union, so please feel free to inquire and purchase products.

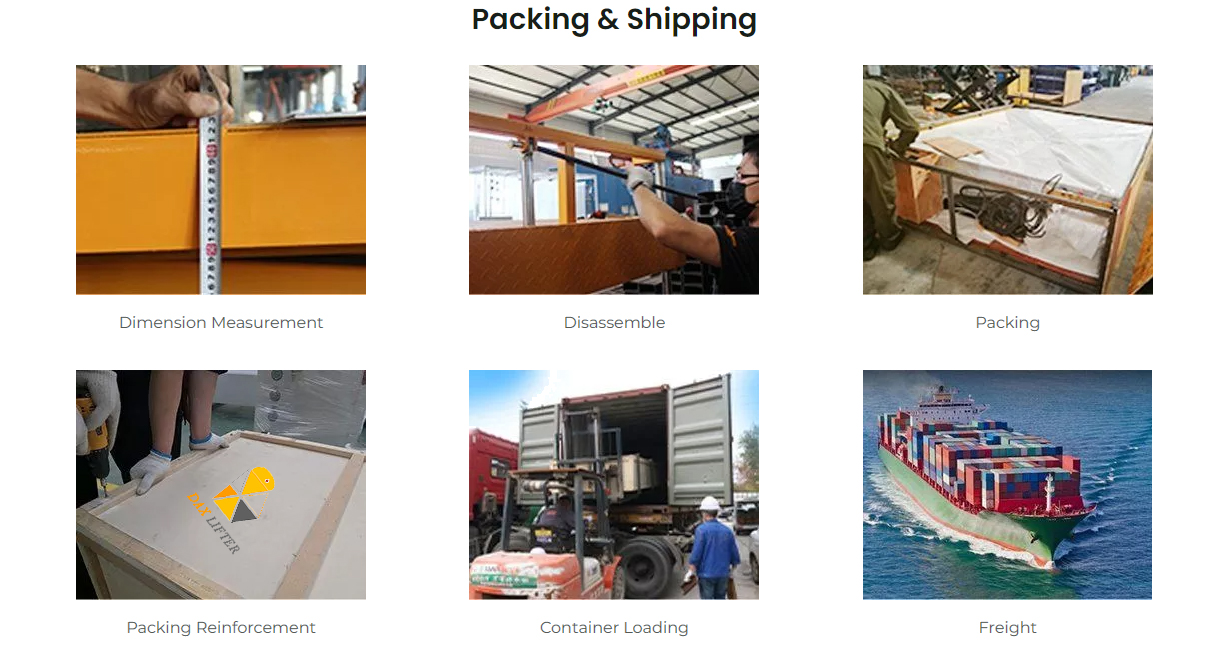

A: We have cooperated with many professional shipping companies for many years, and they will provide us with very good services in terms of ocean transportation.

A: Both the product page and the homepage have our contact information. You can click the button to send an inquiry or contact us directly: sales@daxmachinery.com Whatsapp:+86 15192782747

Video

Specifications

|

Model |

/ |

XPXC400 |

|

Capacity |

kg |

400 |

|

QTY Cup |

pcs |

4 |

|

Capacity for single cup |

kg |

100 |

|

Rotation Angle |

/ |

360° |

|

Weight |

kg |

90 |

|

Wheel size |

mm |

350*85 |

|

Horizontal Adjustment |

mm |

100-200mm |

Why Choose Us

As a professional economic simple glass lifter supplier, we have provided professional and safe lifting equipment to many countries around the world, including the United Kingdom, Germany, the Netherlands, Serbia, Australia, Saudi Arabia, Sri Lanka, India, New Zealand, Malaysia, Canada and others nation. Our equipment takes into account the affordable price and excellent work performance. In addition, we can also provide perfect after-sales service. There is no doubt that we will be your best choice!

Spring support:

The spring buffer prevents the workpiece from being damaged.

Large rotation angle:

Standard configuration manual flip 0°-90°, manual rotation 0-360°.

Optional suction cup material:

According to the different objects that need to be sucked up, choose suckers of different materials.

Alarm device:

When the vacuum of the suction cup is lower than the specified value, it will automatically sound an alarm.

Extended arm:

When the glass size is larger, you can choose to install an extension arm.

Compliance with European standards:

The safety factor is greater than 4.0 times, in line with European safety standards;

Advantages

Check valve:

The one-way valve used in conjunction with the accumulator can prevent accidental power failure during the use of the suction crane, and can keep the workpiece in the adsorbed state for 5-30 minutes without falling;

Energy storage device:

In the entire absorption process, the existence of the accumulator ensures that the vacuum system has a certain degree of vacuum. When an emergency occurs, such as a sudden power failure, the glass can still maintain the adsorption state with the spreader for a long time without falling off, which can effectively protect the operator.

Manually turn the suction cup:

Manually flip and rotate suction cup, which is more convenient to adjust the appropriate angle.

Alarm system:

The sound and light alarm system is to ensure that the suction crane pressure gauge can work safely under the standard vacuum degree above 60%;

Application

Our Australian customers purchase trolley vacuum glass lifter for simple glass installation at low altitude. Trolley vacuum glass lifter is small in size, light in weight, easy to move, and suitable for carrying it to the small space where you need to work.

Features Introduction:

The one-way valve used in conjunction with the accumulator can prevent the suction crane from accidentally powering off during use, and can keep the workpiece in the adsorption state for 5 to 30 minutes without falling;

The sound and light alarm system is to ensure that the suction crane pressure gauge shows that it can work safely at a standard vacuum degree of 60% or more;

Sucker spring support is to meet the uniform force of the workpiece, and the spring buffer to avoid damage to the workpiece;

Standard configuration manual flip 0°-90°, manual rotation 0-360°

Energy storage device: During the entire absorption process, the presence of the accumulator ensures that the vacuum system has a certain degree of vacuum. When an unexpected situation occurs, such as a sudden power failure, the glass can still maintain the adsorption state with the spreader for a long time without falling off , Can effectively protect the operator.

Alarm device: The vacuum system is equipped with a vacuum alarm. When the vacuum degree of the suction glass is lower than the specified value, it will automatically sound the alarm. The alarm is equipped with a battery.

The combination mode and position of the suction cup can be adjusted to meet the changes of different workpiece sizes. When the glass size is large, you can choose to install an extended arm;

The safety factor is greater than 4.0 times, in line with European safety standards;

Purchase guidance

1. The quality of the workpiece to be transported: determines the size and quantity of the sucker

2. The shape and surface condition of the workpiece to be transported: select the type of suction cup

3. Working environment (temperature) of the workpiece to be transported: select the material of the suction cup

4. The surface height of the workpiece to be transported: determine the buffer distance

5. The basic connection method of the suction cup: suction cup, suction cup seat (injection), spring

Maintenance and repair of glass suction crane

1. Glass suction cup: regularly clean the dust of the suction cup and check whether the suction cup is damaged; if it is not cleaned or inspected, it will cause the suction to be loose and fall off, causing a safety accident;

2. Filter: Clean the dust of the filter element regularly to check whether it is blocked or damaged; if it is not cleaned or inspected, it will cause damage to the filter element or damage to the vacuum pump;

3. Screws and nuts: Regularly check whether the nuts and bolts at the hook and connection are loose; if they are loose, tighten them to avoid potential safety hazards;

4. Vulnerable parts: vacuum suction cups, vacuum pump carbon chips, etc.;