Hot New Products Dock Leveller - Vertical Wheelchair Lift – Daxin

Hot New Products Dock Leveller - Vertical Wheelchair Lift – Daxin Detail:

|

Model Type |

VWL2510 |

VWL2515 |

VWL2520 |

VWL2525 |

VWL2530 |

VWL2535 |

VWL2540 |

VWL2550 |

VWL2560 |

|

Max. Platform Height |

1000mm |

1500mm |

2000mm |

2500mm |

3000mm |

3500mm |

4000mm |

5000mm |

6000mm |

|

Load Capacity |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

|

N.W/G.W(kg) |

350/450 |

450/550 |

550/700 |

700/850 |

780/900 |

850/1000 |

880/1050 |

1000/1200 |

1100/1300 |

|

Machine Size(mm) |

2000*1430*1300 |

2500*1430*1300 |

3000*1430*1000 |

3500*1430*1000 |

4000*1430*1000 |

4600*1430*1000 |

5100*1430*1000 |

6100*1430*1000 |

7100*1430*1000 |

|

Packing Size(mm) |

2200*1600*1600 |

2700*1600*1600 |

3200*1600*1600 |

3700*1600*1600 |

4200*1600*1600 |

4800*1600*1600 |

5300*1600*1600 |

6300*1600*1600 |

7300*1600*1600 |

|

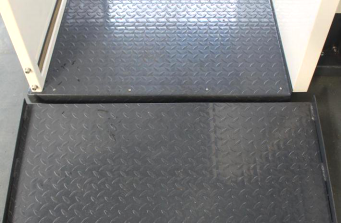

Platform size |

1430*1000mm skid proof checkered steel |

||||||||

|

Min Platform height |

60mm |

||||||||

|

Speed |

0.06~0.1m/s |

||||||||

|

Control voltage |

24V/DC |

||||||||

|

Power Output |

1.1~2.2KW |

||||||||

|

Voltage |

As per your local Standard(single phase or three phase) |

||||||||

|

Drive System |

Hydraulic pump station and electric motor (See details below) |

||||||||

|

Control Mode |

Automatic travel switch(See details below) |

||||||||

|

Drive Control |

Self-resetting system |

||||||||

|

Overload |

Over current relay protection |

||||||||

|

Materials |

Aluminium rails and guard with spraying plastics. (See details below) |

||||||||

|

Working Condition |

Both indoors and outdoors -20°~70°C |

||||||||

|

Entrance-Exit Way |

It’s customized 90°or 180° |

||||||||

|

Installation |

No pit installing,easy to install and remove <3.0m,installed directly on the floor. >3.0m, installed both on the floor and on the wall. |

||||||||

|

Switches (See details below) |

|

||||||||

|

20’ Container Load |

2pcs |

2pcs |

1pc |

1pc |

1pc |

1pc |

1pc |

/ |

/ |

|

40’ Container Load |

4pcs |

4pcs |

3pcs |

3pcs |

2pcs |

2pcs |

2pcs |

1pc |

1pc |

Details

|

Switch 1: Control panel on platform |

Switch 2: Remote control |

|

|

|

|

Switch 3: Two column control: one is on ground floor; another can be fixed at any floor needed. |

Two Travel Switches.One plays an important role of slow down while approaching the ground. The other one cut off the power when reach the bottom. |

|

|

|

|

Whole aluminum rails. All refined aluminum parts are produced by mould,rather than rude welded iron. |

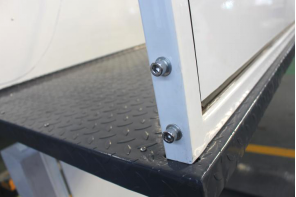

All bolts and screws are stainless steel,being used to assemble and fix each parts together |

|

|

|

|

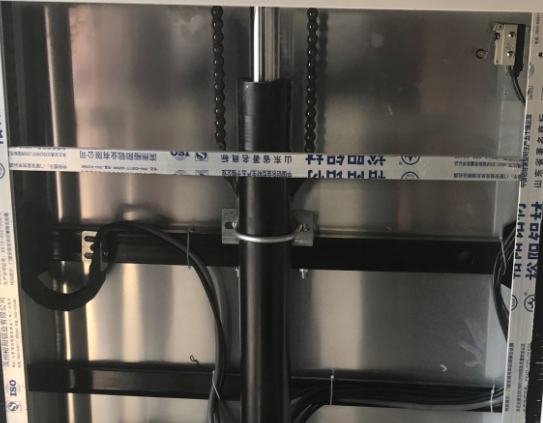

Hydraulic Pump Station and Electric Motor |

Strengthening Ribs,to fix the cylinder and reinforce the whole structure |

|

|

|

|

Up converter:Rise slowly and keep steady during operation. |

The protection Chain. Helping up-down,keep balance and maintain steady,protecting the safety of a suddenly drop. |

|

|

|

|

Safety Sensor. During the falling,it will stop if there are object below. |

Safety Sensor. During the falling,it will stop if there are object below. |

|

|

|

|

Emergency Decline Bar |

Electric Magnetic Valve. Pull the “manual down”to go down through”Emergency Decline Bar” control the electric magnetic valve. |

|

|

|

|

Optional Ramp fixed on the ground,static |

Optional Automatic Ramp, up and down with the car automatically |

|

|

|

|

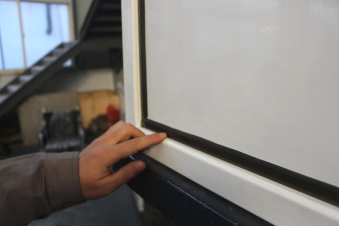

Japan Seal. It ensure the close fitting,more durable |

Slide Block: Nylon-antifraying,good noise reduction |

|

|

|

|

Fixed Structure,strong and durable enough |

Supporting Legs,keep balance |

|

|

|

|

Hydraulic Pump Station and Electric Motor |

Strengthening Ribs,to fix the cylinder and reinforce the whole structure |

Product detail pictures:

Related Product Guide:

TRAILER MAN LIFT equipment is close to the extreme in the production process! Why do you say that? Because from the procurement of raw materials, product design and production process have adopted the world's top technology. Let us discuss these aspects separately. In the procurement of raw materials, we use the highest standard steel in China. High-strength steel can support the basic life of the equipment, which is the most important point for aerial work equipment. The quality and durability of the national standard steel have also reached the relevant world standards. In product design, after inspecting the equipment of relevant famous brands, our designers combined our own advantages and made the final design after numerous updates and improvements. These designs are based on the world's leading level and according to the market needs of different countries, we have also made targeted adjustments. So that TRAILER MAN LIFT equipment can adapt to different working environments, and can also bring the best quality experience to customers. What we need is not only a good aerial work equipment, but more importantly, customer approval. In the production process, we use a lot of high-tech means, such as CNC precision manufacturing, laser cutting, computer numerical control programming and so on. All welding adopts intelligent welding, which minimizes the working errors caused by manual welding. The overall production process uses automated equipment as much as possible, and at the same time reduces errors in each production link to the greatest extent possible. Hot New Products Dock Leveller - Vertical Wheelchair Lift – Daxin , The product will supply to all over the world, such as: Peru, Uruguay, Hungary,

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.